Super-flat high-strength floor

Key words:

Classification:

Product Description

- Product Description

-

- Commodity name: Super-flat high-strength floor

Ultra-flat high-strength floor is the current wear resistance, impact resistance, wet skid resistance, corrosion resistance, weather resistance, low temperature resistance and other comprehensive performance better floor; the floor 'hard and tough' at the same time has the characteristics of high hardness and flexibility; is a non-slip, waterproof, net taste, environmental protection floor. The floor project contains a full set of primer, high-strength self-leveling base series, polyurethane finish, pollution-free construction and use, is a healthy long-life floor products. New earth group to provide professional materials and mature floor construction program, details can call the advisory.

Super-flat high-strength floor

Ultra-flat high-strength floor is the current wear resistance, impact resistance, wet skid resistance, corrosion resistance, weather resistance, low temperature resistance and other comprehensive performance better floor; the floor 'hard and tough' at the same time has the characteristics of high hardness and flexibility; is a non-slip, waterproof, net taste, environmental protection floor. The floor project contains a full set of primer, high-strength self-leveling base series, polyurethane finish, pollution-free construction and use, is a healthy long-life floor products. New earth group to provide professional materials and mature floor construction program, details can call the advisory.

Scope of application:

All kinds of heavy-duty industrial workshops and underground parking lots, including workshops, warehouses, cold storage, large-scale public facilities corridors, outdoor color stands, schools, laboratories, classrooms, offices, kindergartens, shopping malls, hospitals, telecommunications, communications, printing, military industry, aerospace and other industries indoor and outdoor ultra-flat industrial floors.

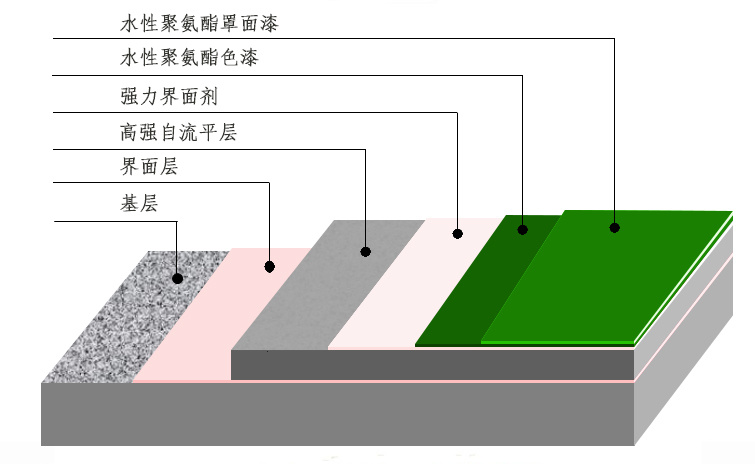

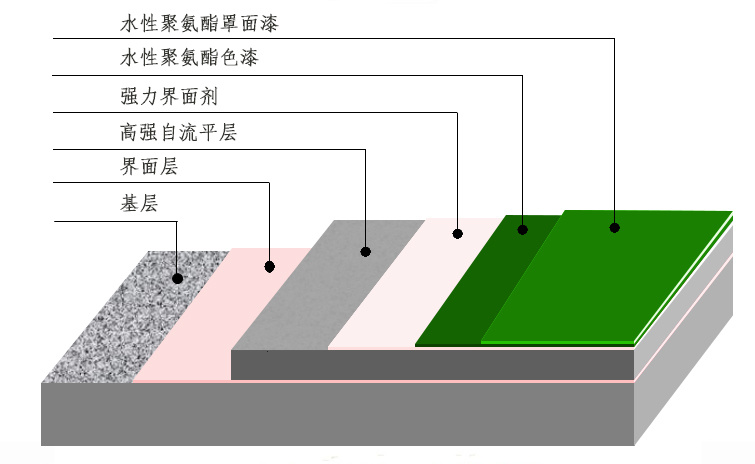

Construction process:

1. Clean the ground:

The construction base shall be leveled, dust and old coating shall be removed, the strength shall meet the requirements of the surface layer, and the water shall be cut off. There shall be no accumulated water, clean and dense. Can not be loose soil, loose particles, gypsum board, paint, plastic, vinyl resin, epoxy resin, and adhesive residue, oil, paraffin, curing agent and greasy and other pollutants attached.

The newly poured concrete shall not be less than 4 weeks, the shell shall be repaired and leveled, the dense base surface shall be polished by mechanical method, and the loose particles on the surface shall be cleaned with water washing and vacuum cleaner, and the surface shall be dried.

The old ground needs to be cleaned and polished as a whole. The holes and cracks in the ground need to be sewn by hand grinder, and then filled with caulking glue.

2. Brushing interface agent

Use the new earth self-leveling interface agent according to the instructions to roll evenly with a wool roller.

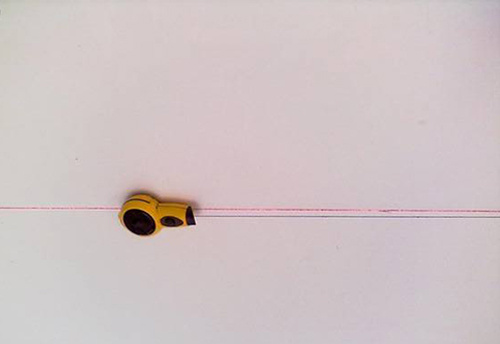

3. Set elevation:

Find the marked high elastic line: according to the horizontal line on the wall, measure the elevation of the surface layer downward and bounce it on the wall.

4. High-strength self-leveling

According to the instructions, add water and use the new earth self-leveling stirring equipment to stir evenly. The stirring time is 1-2 minutes. According to the set elevation line, the pumped self-leveling is evenly poured on the ground, and the defoaming roller is used to eliminate the excess bubbles on the self-leveling surface.

5. Brushing of strong interface agent

Use the new earth strong interface agent according to the instructions to roll evenly with a wool roller.

6. Waterborne polyurethane color paint

The water-based polyurethane paint evenly stirred, stirring time for 3 minutes, with short hair roller coating, roller coating twice is recommended to be better.

7. Waterborne polyurethane finish

The polyurethane matte finish evenly stirred, stirring time for 3 minutes, with short hair roller coating, roller coating is recommended two times the effect is better.

Performance characteristics:

1. Strong overall sense, beautiful and generous, no cracks, silent, non-slip, waterproof.

2, high flatness, 6 meters by the ruler error is less than 2mm.

3. Seamless coating, easy to clean, high hardness, scratch resistance, water resistance, stain resistance.

4, environmental protection, safety, color diversity, long service life, convenient renovation.

5, high strength self leveling construction thickness of up to 1-12cm, can fully achieve the construction thickness of concrete, but also will not crack.

6. High-strength self-leveling does not require manual leveling, which greatly improves construction efficiency and mechanized pumping. A team of 5-6 people can complete 2000-3000 square meters of super-flat ground in one day.

7. High strength: 35 MPa -40 MPa.

Product inquiry

Related Products

Jinan Headquarter: 19th Floor, Greenland Colorful City, East Square of Jinan High Speed Railway

Feicheng Production Base: Feicheng Xinxing Industrial Park, Feicheng City, Shandong Province, China

Yucheng Production Base: Yucheng High-tech Development Zone, Shandong Province, China