Focus on the field of construction products

Company covers an area

Annual output of redispersible latex powder

Cumulative Service Customers

Shandong Xindadi Industrial Group

Has been committed to the development and production of high-quality products for the construction industry

Shandong Xindadi Industrial Group Co., Ltd. (referred to as Xindadi Group) was established in 1998. It is a provincial high-tech enterprise integrating scientific research and development, production and sales, and technical services. The group is headquartered in Jinan, Shandong Province. There are two processing bases in Feicheng and Yucheng, covering an area of 120,000 square meters. The annual output of dispersible latex powder is 36000 tons. It is currently one of the larger redispersible latex powder production bases in Asia, at the same time, it is also a large dry-mixed mortar production enterprise in Shandong Province.

View more>

Product recommendation

Xindadi Group has been committed to R & D and production of high-quality, high-tech products for the construction industry to improve the scientific and environmental protection of construction. The main products are: re-dispersible latex powder, polycarboxylate superplasticizer, cellulose, mortar defoaming agent, self-leveling cement and other products.

Special rubber powder for XDD-730 tile adhesive

Polycarboxylate superplasticizer

Defoamer

Hydroxypropyl methyl cellulose

Silicone water repellent

Dispersant

Self-leveling mortar

XDD-740 self-leveling special rubber powder

Enterprise strength

Strong scientific and technological research and development strength, strict quality control system

Xindadi Group has been committed to the development and production of high-quality products for the construction industry to improve the scientific and environmental protection of construction. The main products are: re-dispersible latex powder, powder polycarboxylate superplasticizer, defoamer, self-leveling cement (mortar), thick layer self-leveling cement, high strength self-leveling cement, waterproof self-leveling cement, self-leveling cement masterbatch, permeable concrete binder, cellulose, PP fiber, calcium formate, water repellent, emery wear-resistant aggregate, grouting material, plastering gypsum, ceramic tile, adhesive, interface agent, PVC floor glue, waterproof mortar, external wall insulation powder, JS FS composite insulation outer template, real stone paint and other products.

Application areas

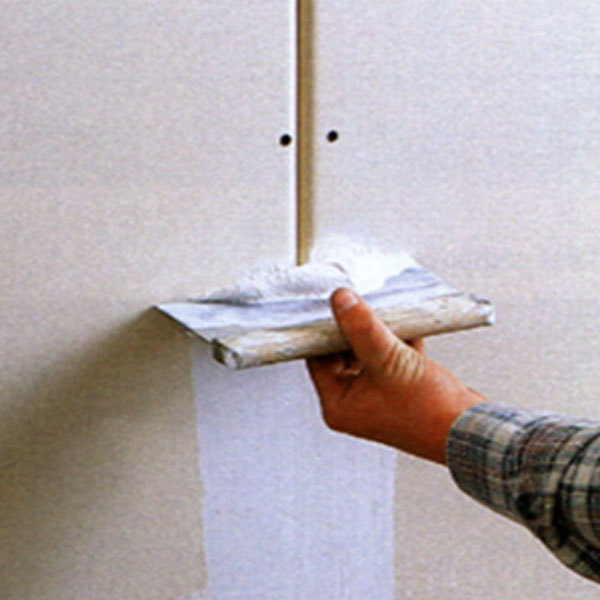

The main applications are: putty powder, tile glue, self-leveling mortar, bonding mortar, plastering mortar, repair mortar, plastering mortar, etc.

News Center

5 Time Points to Be Grasp in Using Tile Glue

The operable time is also called the storage time, which refers to the time interval when the consistency of the tile glue is gradually thickened in the barrel after being stirred until it cannot be used. The tile adhesive can be operated for 3 hours under standard conditions (20 ℃, 50% humidity). The actual operation time depends on the weather conditions, and the operation time will be shorter in the hot and windy weather. Such as in summer, tile glue should be controlled within 1 hour.

The role of rubber powder and cellulose in ceramic tile adhesive

Latex powder-improves the consistency and smoothness of the system in the wet mixing state. Due to the characteristics of the polymer, the cohesion of the wet mixing material is greatly improved and contributes greatly to the workability. After drying, it provides adhesion to smooth and compact surface layer, improves the interface effect of sand, gravel and pores, and can form a film at the interface under the premise of ensuring the addition amount, so that tile adhesive has certain flexibility and reduces elastic modulus, the heat deformation stress is absorbed to a large extent. In case of water immersion in the later period, there are also stresses such as waterproof, buffer temperature and inconsistent material deformation (ceramic tile deformation coefficient 6 × 10-6/℃, cement concrete deformation coefficient 10 × 10-6/℃) to improve weather resistance. Hydroxypropyl methyl cellulose HP cellulose --- provides good water retention and workability for new mortar, especially for the wetting area. In order to ensure the smooth progress of the hydration reaction, the substrate can be prevented from excessive water absorption and surface water evaporation. Due to its air entraining (1900g/L ---- 1400g/LPO400 sand 600HP cellulose 2), the bulk density of tile glue is reduced, materials are saved and the elastic modulus of hardened mortar body is reduced.

Effect of Hydroxypropyl Cellulose Ether in Gypsum Mortar

As an important part of the tile paving project, the caulking agent not only improves the overall effect and contrast effect of the tile facing project, but also plays an important role in improving the waterproof and impermeability of the wall. A good ceramic tile adhesive product, in addition to rich color, uniform and no color difference, should also have the functions of easy operation, fast strength, low shrinkage, low porosity, waterproof and impermeability. Cellulose ether can reduce the wet shrinkage rate while providing excellent operation performance for caulking agent products, and the amount of entrained gas is small, and the effect of cement hydration is small.

Get the program immediately consulted

The company has always adhered to the tenet of "quality-oriented, customer first, and abiding by the contract". With professional management team, scientific research and development, and strict quality control system, the products are sold well in more than 30 provinces, cities, and autonomous regions and exported to Southeast Asia and South America., Eastern Europe and other countries.

Jinan Headquarter: 19th Floor, Greenland Colorful City, East Square of Jinan High Speed Railway

Feicheng Production Base: Feicheng Xinxing Industrial Park, Feicheng City, Shandong Province, China

Yucheng Production Base: Yucheng High-tech Development Zone, Shandong Province, China